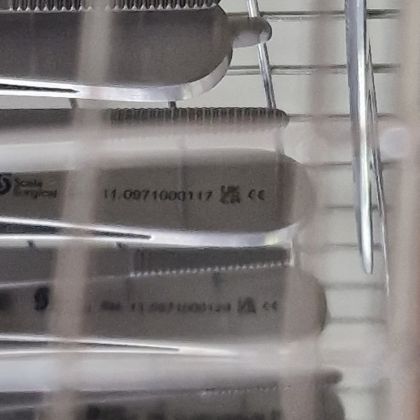

Passivation is a critical step in ensuring the durability and performance of stainless steel surgical instruments. At SCALA Surgical, we go beyond compliance by adopting environmentally friendly practices, such as using citric acid in the passivation process. This choice not only adheres to ASTM A967 standards but also aligns with our commitment to sustainability.

The process involves immersing instruments in a citric acid solution, which effectively removes surface contaminants like iron particles or oxide scales. This treatment restores the stainless steel's natural corrosion-resistant properties by forming a thin, protective oxide layer. This "passive" layer acts as a barrier against moisture, disinfectants, and sterilization processes, ensuring the instrument’s longevity in demanding medical environments.

Our use of citric acid underscores our dedication to eco-friendly manufacturing. Unlike traditional methods that use nitric acid, citric acid is safer for the environment while delivering the same level of protection and performance. This approach minimizes environmental impact while maintaining the highest standards of quality.

By adhering to ASTM A967 and employing sustainable methods, we ensure that every instrument meets rigorous quality benchmarks. Proper passivation not only reduces the risk of corrosion but also extends the lifespan of surgical instruments, translating to lower maintenance costs and better outcomes for healthcare providers and their patients.

At SCALA Surgical, our principles of honesty and integrity are reflected in every aspect of our manufacturing process. We are committed to producing reliable, high-quality instruments that prioritize both performance and environmental responsibility. Passivation is not just a step in production—it is a testament to our values and dedication to excellence.